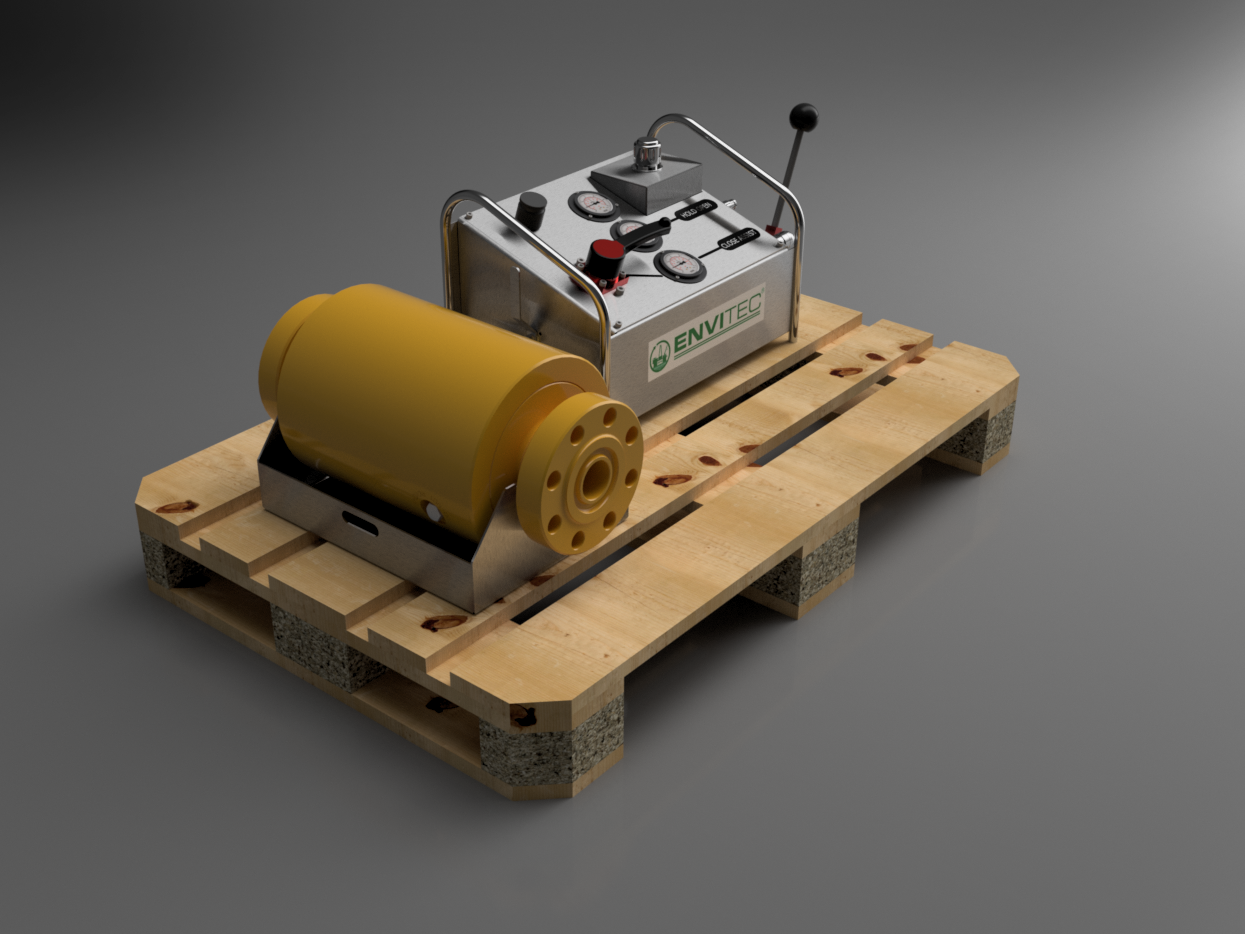

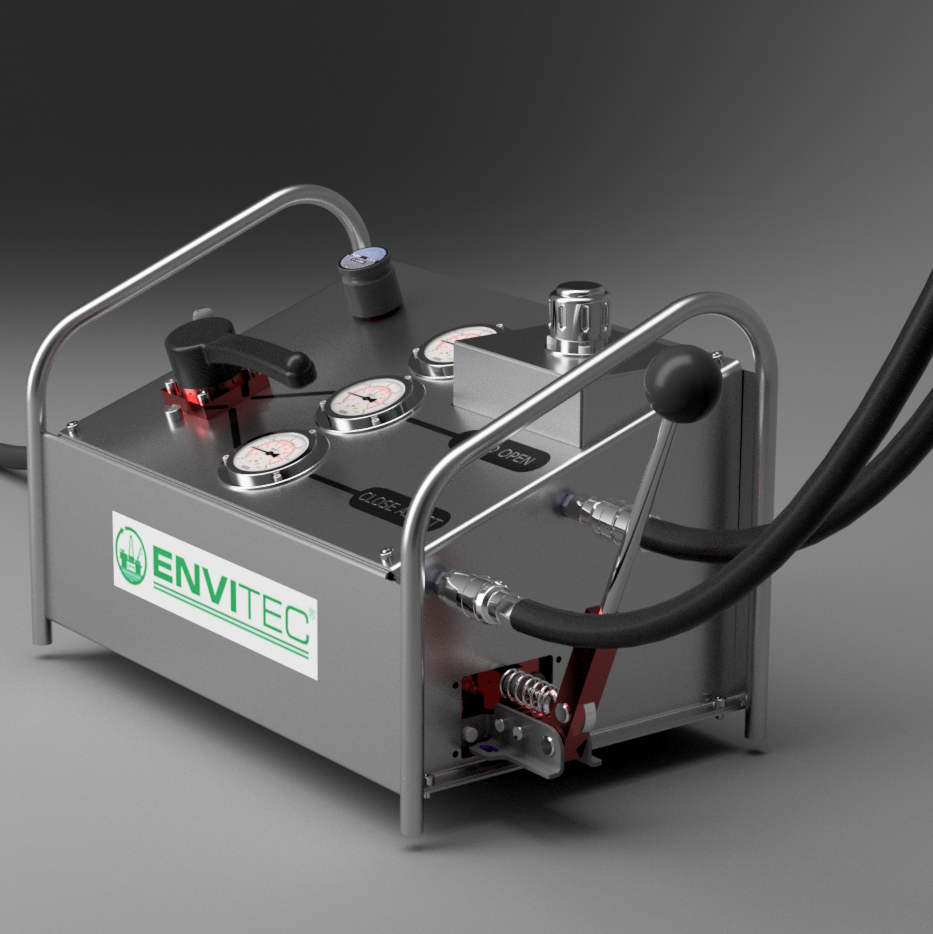

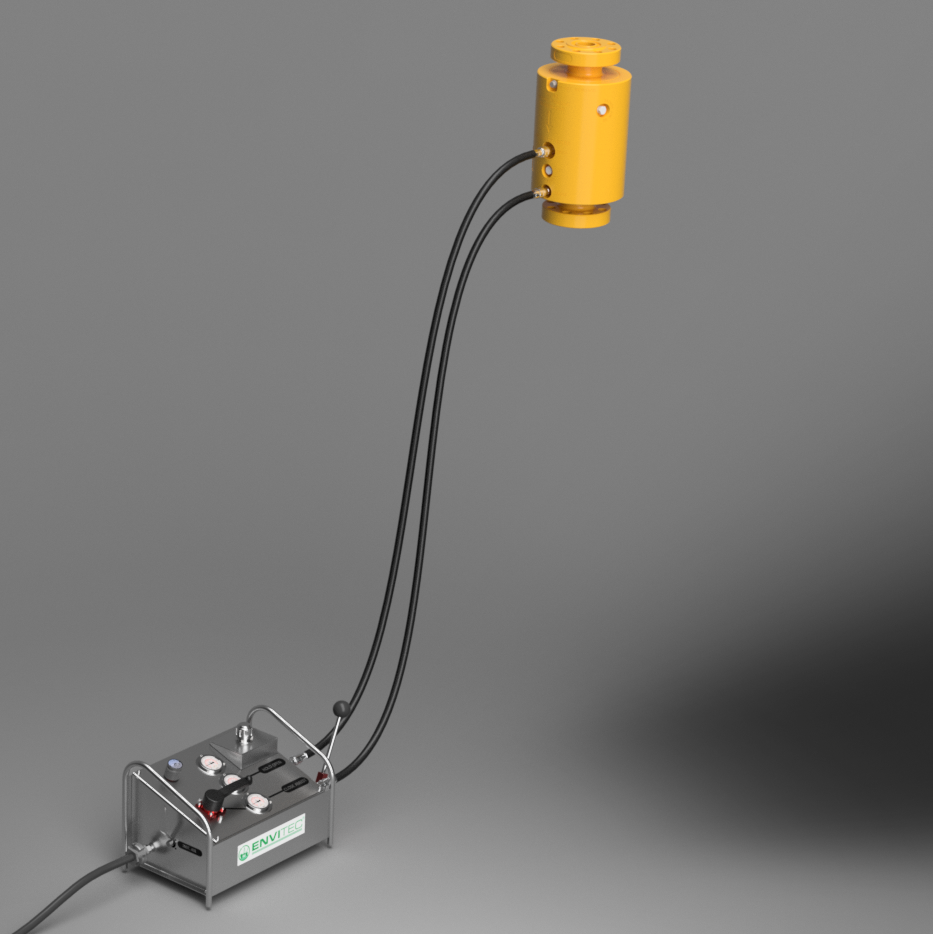

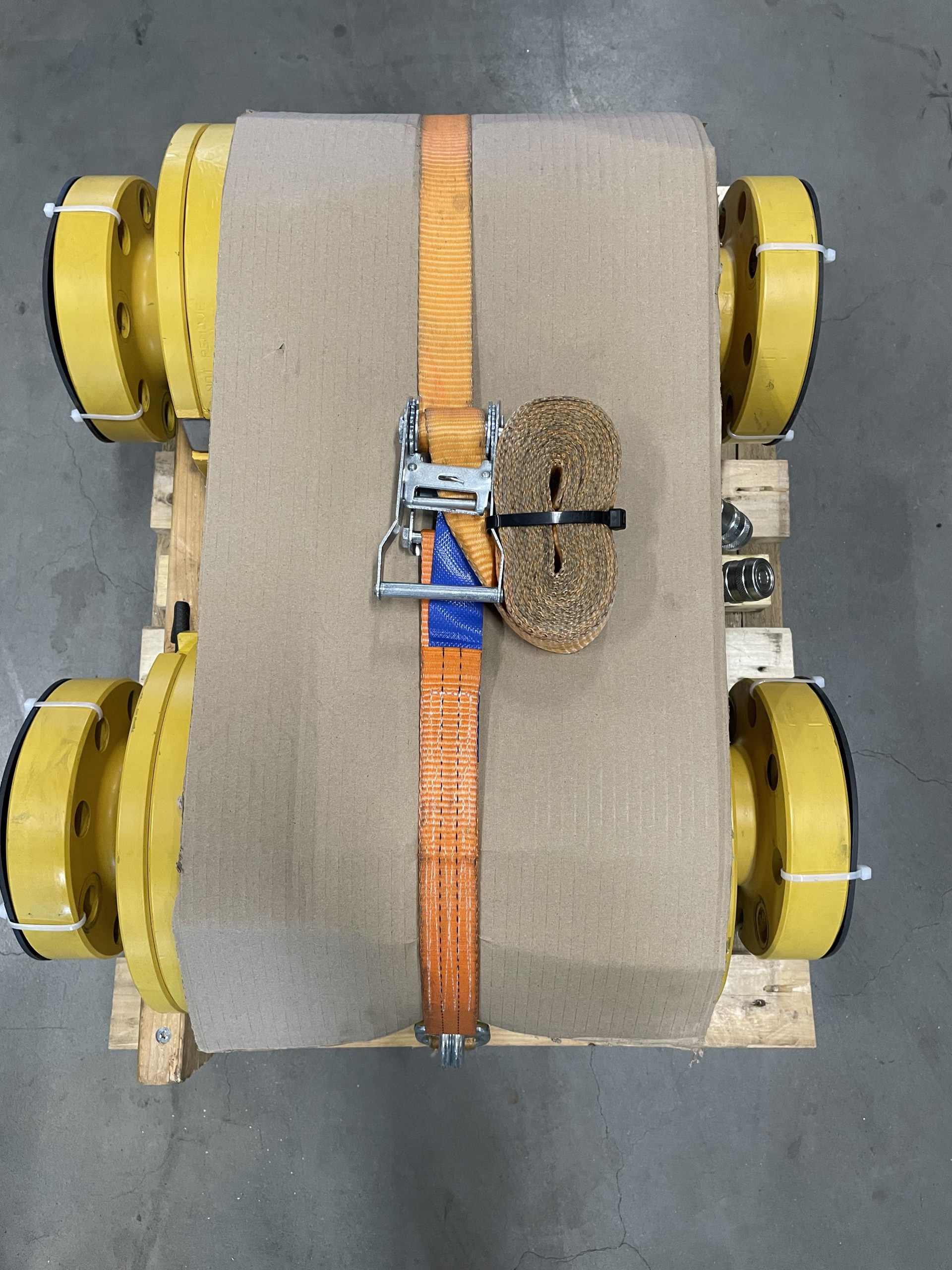

Check valveEnvitec hydraulic check valve

HYDRAULIC HOLD OPEN CHECK VALVE

The main purpose of the Hydraulic Hold Open Check Valve unit is to eliminate situations where hydrocarbons accidentally enter the fluid return from the Well Test String to the rig cement unit, either during well test operation if the tree valve is not holding, or during well kill operation.

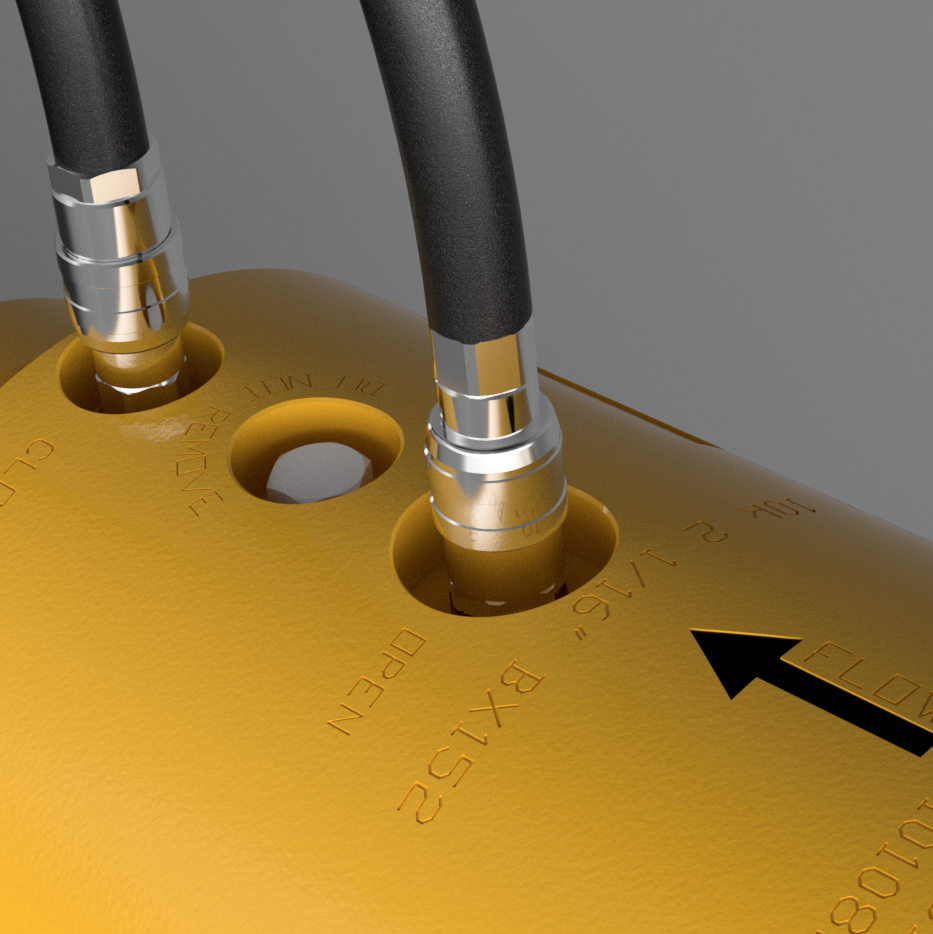

The valve has a full 2” ID minimum bore. With the hydraulic hold open mechanism, the flapper element is completely out of the flow or fluid path when engaged. This eliminates any possibilities to flow cut the flapper element and seat when bleeding off pressure at the cement unit. Volume control is essential and is maintained by using a hold open check valve. The main seal is metal to metal between the flapper and the seat. As a secondary seal an o-ring is installed into a special o-ring groove. This prevents the o-ring from falling out during high flow operation.

Check valve flyer