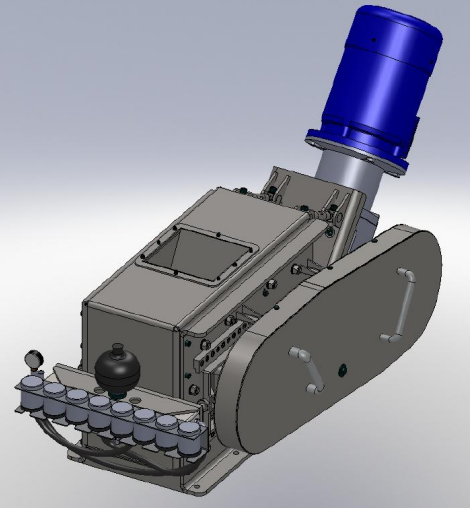

Envitec roller mill

ENVITEC ROLLER MILL

The Roller Mill HVS-300-300 is made of stainless steel and is intended for the specific purpose of crushing “proppants” or “kaks”.

The Roller Mill HVS-300-300 is equipped with 2 mill rollers coated with hardmetal. These are individually, but synchronously, driven “fixed rollers”, which are adjusted to have a fixed desired distance, and thus are not in direct contact.

To ensure against overloading or foreign elements in the product, the rollers are fixed by means of a hydraulic tensioning system enabling the rollers to open. The hydraulic tensioning system consists of 2 cylinders and 1 diaphragm accumulator and a manometer. The pressure is applied/adjusted for 1 roller by means of a manually activated oil pressure pump.

At the outset, the pressure has been fixed at 50 bar, i.e., the pressure is 2500 kilos per cylinder, entailing a roller pressure of 5000 kilos.

The rollers are driven by cog wheel belt transmission and an ATEX approved gear motor (6.30kW, 1740r/min, 440V Y, 60Hz, 11.40A, cos. phi 0.82, IEC, IP 56, IMV1/IM3011, IC411, ICLF, Ex de, IIC, T4, L, 40°C, 1000m) mounted on an adjustable console.

The rollers are secured by means of adjustable PUR sealings at the roller sides, ensuring that no product may pass without being crushed. At the shaft passages, shaft stuffing boxes type WA 60-80-8 are mounted.