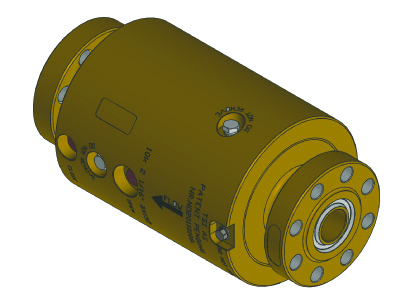

Hydraulic Hold Open Check Valve

Issues

The main purpose of the Hydraulic Hold Open Check Valve unit is to eliminate situations where hydrocarbons accidentally enters the fluid return from the Well Test String to the rig cement unit, either during well test operation if the tree valve is not holding, or during well kill operation.

By introducing a Hydraulic Hold Open Check Valve the requirement for man riding operations is eliminated, improving the HSE potential significantly.

A check valve shall be used according to Norsok D-010 rev 4, Table 34 and Norsok D-007 Annex C, C2 last bullet, “Should be remote operated and have a lock open facility”

This is the only DNV certified available in the industry at present time. (2015).

Description

Features

The valve has a full 2” ID minimum bore. With the hydraulic hold open mechanism, the flapper element is completely out off the flow or fluid path when engaged. This eliminates any possibilities to flow cut the flapper element and seat when bleeding off pressure at the cement unit. Volume control is essential and is maintained by using a hold open check valve.

The valve has a full 2” ID minimum bore. With the hydraulic hold open mechanism, the flapper element is completely out off the flow or fluid path when engaged. This eliminates any possibilities to flow cut the flapper element and seat when bleeding off pressure at the cement unit. Volume control is essential and is maintained by using a hold open check valve.

The main seal is metal to metal between the flapper and the seat. As a secondary seal an o-ring is installed into a special o-ring groove. This prevents the o-ring from falling out during high flow operation.

Operation

The Hydraulic Hold Open Valve is installed on the Surface Test Tree, bolted onto the body between the flexible kill hose and the kill wing valve.

The main seal is metal to metal between the flapper and the seat, secondary seal is an o-ring installed in a special o-ring groove that prevent the o-ring from loosening during high flow operation . This also ensures efficient pressure integrity from zero pressure applied form the tubing side. The spring in the control chamber will return the flapper into its normal position when there is no hydraulic pressure applied through the control line, we have kept a very low spring force acting on the flapper, the intention of having this positive force in place is to assist closure in operation when there is very little flow forms the tubing side returning back to the cement unit. The internal pressure from the well bore will always act to close the valve, maintaining the fail close functionality in place. In addition a close assist control line can be utilized.

Specifications

Hydraulic Hold Open Check Valve

Description: Normal operated closed, hydraulic hold open.

Part number: TSI-110203

Working Pressure: 10 K PSI, 690 Bar

Working Temperature: -21 to 121 Celsius

End Connections: 2 1/16 in -10K, BX 152 Seal ring

Hydraulic connection port: 1/2” NPT Female

Dry Weight: 175 kg

Design Codes: API-SPEC-6A, DNV-OS-E101

Material: AISI 4130-75k API-6A-PSL3, AISI 4140 90KSI

Patent Pending number: NO20110108

Type Approved, DNV Certified: Yes